Pumps

Water Pump

1. HVAC Pumps

(End Suction Pumps)

CONSTRUCTION

- According to DIN EN 733 (DIN 24255) standards. Casing, cover and closed radial impeller in cast iron GG25.

- Stainless steel shaft and mechanical seal.

- Centreline discharge

- Back pull-out rotating element can be

- removed without disturbing pipe work

- The option close coupled with three-phase motor of 2900 rpm, IP55 protection, insulation class F and 1450 rpm.

- Version for applications with lower head and lower noise levels.

- This pump can be supplied with bronze impeller.

WORKING LIMITS

- Flow 2 up to 900 m3/h

- Head 3 up to 150 m

- Maximum temperature of the water: 120ºC

- Maximum working pressure: 10 bar and 16 bar

Note: The hydraulic performance according to DIN 1944 III or ISO 9906 grade 2.

Split Casing Pumps

CONSTRUCTION MATERIALS

- These pumps can be constructed by the following materials: Cast iron, ductile cast iron, carbon steel, stainless steel, others

- Impeller: Cast iron

- Shaft: Stainless steel, cold rolled steel

- Pump size: up tp DN400

WORKING LIMITS

- Maximum flow rate: 25000 m3/h

- Maximum head: up to 230 m

- Liquid temperature: up to +105ºC

- Maximum operating pressure: 30 bar

Inline Pumps

CONSTRUCTION MATERIALS

- Pump body: Cast iron

- Impeller: Cast iron / Bronze

- Bracket/Cover: Cast iron

- Shaft: Stainless steel

WORKING LIMITS

- Maximum flow rate: up to 300 m3/h

- Maximum head: up to 68 m

- Maximum liquid temperature: -10ºC a +130ºC

- Maximum working pressure: up to 10 bar

2. Booster Units

DESCRIPTION

- Model: AQUA Premium / Master / Profissional / Domus

- Type: Constant Speed / Variable speed

- Start: DOL / Star Delta / Frequency Converter

- of pumps: up to 4 pumps

PUMPS

- Type: Horizontal / Vertical multistage

- BMH / BMV / BMX

- Construction: AISI 304 / 316 stainless steel

- Power: from 0.55 kW up to 37 kW

SYSTEM CONSTRUCTION

- Base frame: Mild Steel

- Painting: Resistance to humidity

- Suction &Discharge manifold: AISI 304 stainless steel

- Valves: Cut off and non-return per pump, as system cut off

- Discharge: Pressure transducer and pressure gauge

- Tank: Replaceable membrane, for drinking water, up to 300 l

MOTOR

- Three-phase power supply at 400V (50 Hz) for electric pumps between 0.75 kW and 37 kW

WORKING LIMITS

- Maximum flow rate: up to 200 m³/h

- Maximum head: up to 138 meters

- Shut off pressure: up to 16.6 bar

3. Drainage / Sewage Pumps

APPLICATIONS

- Pumping domestic and industrial sewage

- Pumping sewage in small wastewater stations

- Drainage of industrial wastewater and rainwater

- Garden irrigation, fountains and water systems

CONSTRUCTION MATERIALS

- Pump body: Cast iron / AISI 304 stainless steel

- Impeller: Cast iron / AISI 304 stainless steel

- Shaft: AISI 403 stainless steel / AISI 303 stainless steel

- Seal type: Double mechanical seal

WORKING LIMITS

- Maximum flow rate: up to 330 m3/h

- Maximum head: up to 40 m

- Maximum passage of solids: up to 100mm

- Maximum liquid temperature: +40ºC

4. Circulation Pumps

CONSTRUCTION MATERIALS

- Pump body: Cast iron / Bronze

- Impeller: Technopolymer / AISI 316

- Shaft: AISI 420 / AISI 316

- Jacket: AISI 316

WORKING LIMITS

- Maximum liquid temperature: 110ºC

- Maximum Service Pressure: 10 bar

- Maximum Ambient Temperature: 40ºC

MOTOR SPECIFICATIONS

- Type: Motor with permanent magnets

- Voltage: 1x230V / 3x400V

- Insulation Class: H / 200

- Protection Class: IP44

- Rotation: Three speeds

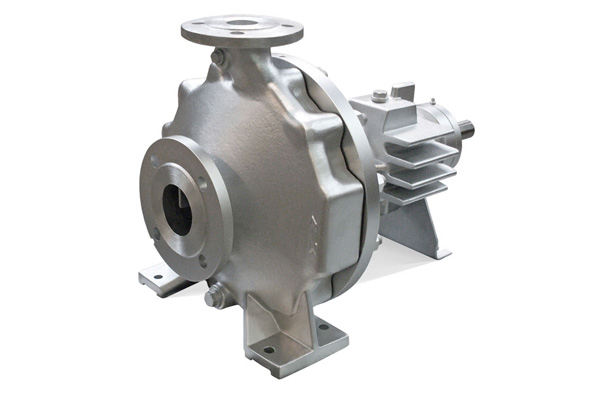

5. Industrial Pumps ISO 2858

APPLICATIONS

- Pulp&Paper industry

- Petrochemical and chemical industries

- Food&Beverage industries

CONSTRUCTION MATERIALS

- Body Pump, shaft and impeller construction materials can be from, nodular cast iron (EN-GJS-400-15), carbon steel (GS-C25) or others

- Impeller: Closed type with rear blades to compensate axial thrust

- Seal type: Mechanical

WORKING LIMITS

- Maximum flow rate: up to 300m3/h

- Maximum head: up to 100m (50Hz)

- Liquid temperature:

- Hot water – up to +180ºC

- Termofluids – up to +300ºC

- Maximum operating pressure: 16 bar

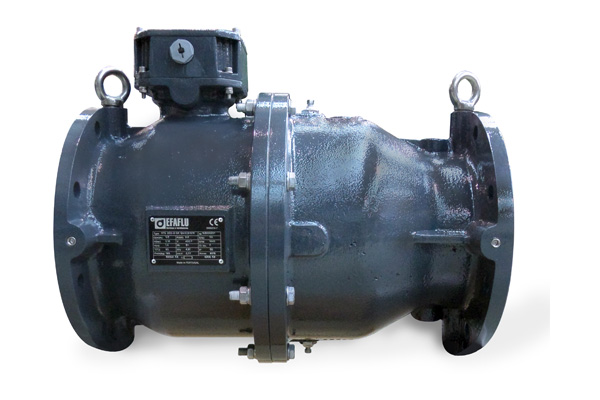

6. Transformer Oil Pumps

CONSTRUCTION MATERIALS

- EN-GJL-250 or EN-GJS-400 Cast Iron Casing

- Aluminium impeller

- Viton gaskets and AISI 316 stainless steel accessories

- Terminal box with IP56 protection

MOTOR

- 4 poles 0.75 and 7.5 kW

- 6 poles 0.75 and 5.5 kW

WORKING LIMITS (50 Hz)

- Maximum flow rate: up to 300 m³/h

- Maximum head: up to 15 meters

- Temperature: -20ºC up to +115ºC

- Installation: Horizontal or vertical

Fire Pumps

CONFIGURATION

Single or multiple pump package sets,horizontal end suction close and longcoupled, split case long coupled, multi-stage, multi-outlet and vertical turbine all electricmotor or engine driven

DISCHARGE & PERFORMANCE

- End Suction (Single Stage) – 32 mmto 150 mm. Outputs up to 500 m3/h, Heads up to 15.2 bar

- Split Case – Outputs up to 230 l/s Heads up to 60 bar, Outlet 80 mm to 300 mm.Heads up to 44.5 bar (Approved fire set)

- Multi-stage multi-outlet – 100 mm to125 mm. Outputs up to 315 l/s.Heads up to 60 bar

- Vertical Turbine – 200 mm to 508 mmOutputs up to 9000 m3/h

- Multi-stage / multi-outlet – 50 mm to250 mm. Outputs up to 850 m3/h.Heads up to 850 m. Up to 140 oC

FEATURES

- Meeting the requirements of worldwideinsurance and approvals bodies

- End Suction – Centreline discharge backpull-out rotating element can be removedwithout disturbing pipe work

- End Suction – Close coupled, space andcost saving solution

- Axially split case rotating element can beremoved without disturbing pipework

- Rigid, box-section baseplates for end suctionand split case long coupled packages

- Stainless steel shaft with tight tolerancesdesigned to transmit the maximum loadacross full pump curve

- Bearing arrangements of ample proportion

- IE2 motors fitted as standard

- Impellers machined and hand finished tomeet customer duty

We Provide the Best Service in Industry

The main reason to offer a free consultation is it gives you an opportunity to connect one-on-one with your prospects.